Your Cart is Empty

August 17, 2021 2 min read

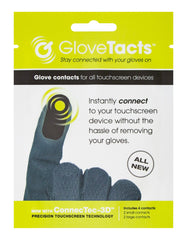

Back in 2014 we started work on a way to make gloves touchscreen so we didn't have to remove gloves to work with touchscreens, and after seeing there was an opportunity to commercialize the product we scaled and went to market.

The first version, called v1 for version 1, launched late in 2015. It was made using a conductive material also used to make gloves touchscreen, meaning glove manufacturers cut it and stitched it to gloves and then sold the gloves as touch screen compatible. We used processes called die cutting and laminating to shape the material and add an adhesive layer to it. This was done by a rotary machine at a vendor right in Los Angeles.

Separately, we designed a jacket into which the laminated material would be inserted prior to retail. It was beautiful and substantial!

V1 as popular with motorcyclists, but it did not take long to realize there was room for improvement. Firstly, they had a tendency to peel off the glove, mostly due to the 0.8mm height which created a lip that was caught on surfaces as the glove was used. The adhesive itself was of concern because if it got warm, it would become gooey, compounding the lip problem Lastly, the material itself was prone to failure, despite being supplied by one of the leading manufacturers of glove materials.

|

|

V2 launched in 2019. The product was completely redesigned gone was the textile material, as we were able to develop a conductive vinyl film that was just 0.05mm thick, and match it to a new type of adhesive that promised more stability. The packaging changed to a lightweight and small aluminized pouch that was easier and cheaper to ship to customers all over the world.

|

|

V2 was conductivity was much improved over v1, which meant more responsive touch for more gloves. We did introduce the concept of sticker sizes, as smaller, thinner gloves naturally require less support to achieve touch compatibility, while thicker, insulated gloves worked better with larger stickers.

While V2 greatly improved on V1, it too had a couple of flaws. First, the vinyl itself was easy to damage with wear, and secondly, the adhesive problem repeated itself... on warm days it became gooey which affected the sticker positioning on the glove.

It was time for the next iteration.

V3 launched in late December of 2020. Once again, everything changed in order to solve previous problems. A new film is made of polyurethane, a durable material that is hard to tear or wear through. And the adhesive is completely reengineered to improve stability at extreme temperatures without becoming gooey.

The PU film is the most conductive yet, and due to this we've been able to make a single sticker size work with insulated and non insulated gloves. We also include a total of 6 stickers in each pouch to maximize value.

Customers are able to maker more gloves conductive, or can keep spares for when they need them.

GloveTacts V3 has proved to be a durable and reliable way to make gloves touch screen compatible.